Take precise control of process with the best selection of process instrumentation and control solutions in the Midwest. Flow and pressure measurement, temperature, humidity, pH; whatever you need to measure we have the instruments to do it.

Durkin’s team has been specializing in process instrumentation for since 1958. Our experts can help you select, install, and integrate the right process instrumentation for your application. We a proud to distribute top brands, primarily: ABB process instrumentation, Dynasonics, KOBOLD and more.

Explore our full instrumentation catalog below, or contact Durkin (314) 432-2040 for more information.

Instrumentation

Overview

Data

Overview

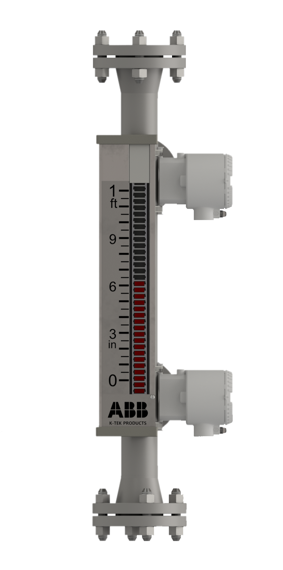

- Highly visible level indication with no process fluid in contact with the glass

- All construction in-house by code certified welders

- Float designed and weighted for maximum accuracy with 75 grams minimum upward buoyant force

- Transmitter and switch options which can be installed, adjusted and maintained with no process interruption

- Safe for corrosive, flammable, toxic, high-temperature and high-pressure applications

- Rugged design - low or no maintenance

Data

Overview

ABB's K-TEK level products' patented sensor technology allows the LMT series transmitters to be used in the most challenging of industrial level applications such as interface measurement, compressor level and separator level applications. In addition, the LMT Series Level Transmitters are the only magnetostrictive level transmitters in the world to be certified for use in SIL2 and SIL3 systems per IEC61508. Every day, we solve high accuracy and challenging applications. We can help you with yours. ABB's K-TEK level products' magnetostrictive transmitters are used extensively around the world to provide continuous level indication and transmission of an analog and/or digital signal for monitoring or control. The unique design allows increased level sensing resolution which is more than 100 times greater than a conventional reed switch type device. The Magnetostrictive Level Transmitter versatility allows direct in-tank installation (LMT100) or external mounting (LMT200) to a magnetic level gauge. HART and FOUNDATION Fieldbus options make our magnetostrictive level transmitters easy to connect digitally to most control systems.Customer benefits:

- High Accuracy

- High Reliability

- No calibration required

- No Maintenance

- Oil and Gas

- Petrochemical

- Chemical

- Power Generation

- Water and wastewater treatment

- Pulp and Paper

- Biotech

- Marine

Overview

Accessories

Dust tube – Avoids dirt or splashing liquids on the window Cooling tube – Increases max. process temperature to 280°C/535°F Heated window – Prevents condensation on window (requires 4 wire power) Integral Through-the-Glass user interface – Configuration directly on the unit Rotating bracket – Ideal for aiming the LLT100 laser beam Swivel flange – Provides precise aiming of the LLT100 laser beam. Especially useful in liquid applications Laser pointer tool – Used to provide a visual reference when aligning LLT100Process flanges

Universal flange (aluminum or stainless steel) – Flange bolt pattern fits both 2 in. ASME150 and DN50 PN 16 – Maximum pressure: 2 bar (29 psi) – Hazarous area class 1 / division 1 (zone 1) High pressure – 2 in. class 150 flange – 2 in. class 300 flange – DN50 PN16 flange – DN50 PN40 flange – Hazardous area class 1 / division 1 (zone 1) – Can be used to form a barrier to zone 0 Hygienic interface – 4 in. triclover clampData

Measurement

- Range 0.5 to 30 m (2 to 100 ft) for liquids 0.5 to 100 m (2 to 330 ft) for solids 0.5 m to 200 m (2 ft to 660 ft) for positioning applications with reflective target

- Resolution 5 mm (0.2 in)

- Typical accuracy ±11 mm (0.4 in)

- Measuring beam Laser wave length: 905 nm, eye safe, Class 1

- Laser beam divergence < 0.35°

- Environmental conditions

- Operating temperature –40° to +60°C (–40 to +140°F), up to 280°C (535°F) with cooling tube

- Storage temperature –40 to +85°C (-40 to +185°F)

- Survival temperature –40°C to +80°C (–40°F to +175°F)

- Process pressure – Base model: –1 to +2 bar (29 psi) – Hygienic model: –1 to +1 bar (15 psi) – Pressure-rated model: –1 to +49.6 bar (719 psi), depending on flange

Output

- Analog 4 to 20 mA, NAMUR compliant

- Digital HART 7 (multi-variable output)

- Communication Local HMI, EDD/DTM, handheld

Power supply

- Powered from the loop 4 to 20 mA, 16 to 42 V DC

- Heated lens option 24 V DC (3W)

Mechanical

- Enclosure material Powder coated aluminum (standard), 316L stainless steel (option)

- Dimensions – Universal - flat flange W 247 x H 215 x D 165 mm (9.7 x 8.5 x 6.5 in.) – Class 150 - raised flange W 240 x H 242 x D 154 mm (9.5 x 9.5 x 6.1 in.) – Class 300 - raised flange W 247 x H 242 x D 165 mm (9.7 x 9.5 x 6.5 in.) – DIN PN 16 - raised flange W 247 x H 242 x D 165 mm (9.7 in x 9.5 x 6.5 in.) – DIN PN 40 - raised flange W 247 x H 242 mm x D 165 (9.7 x 9.5 x 6.5 in.) – Hygienic flange W 223 x H 215 x D 137 mm (8.8 x 8.5 x 5.4 in.)

- Weight of standard model – Aluminum enclosure with universal aluminum flange: 3.7 kg (8.2 lb) – 316L SST enclosure with universal stainless steel flange: 8.6 kg (19.0 lb)

- Weight of pressure rated model – Aluminum enclosure: 6.7 to 7.2 kg (14.8 to 15.9 lb), depending on flange – 316L SST enclosure: 10.0 to 10.5 kg (22.1 to 23.2 lb), depending on flange

- Weight of hygienic model – Aluminum enclosure: 5.8 kg (12.8 lb) – 316L SST enclosure: 9.1 kg (20.1 lb)

- Protection class IP66 / IP67/ Nema 4 (SS version 4X)

- Process fitting – Flange (ASME 2”, DN50) – Hygienic fitting / tri-clamp 4 in. (ISO2852)

- Wetted parts – Aluminum, cemented borosilicate window (base model) – 316L SST, cemented borosilicate window (base model, hygienic model) – 316L SST, fused borosilicate window (high pressure models)

Operation

- Display – Integrated 128x64 pixels LCD display with TTG (Through-The-Glass) interface

- Software features – Volume computation, damping, filtering, thresholds/alarms, user-defined display(with HMI)

- Approvals CE, ATEX, IECEx, FM, 3A

Overview

- High accuracy: 0.01% of full scale or + 1.27mm

- Never requires re-calibration: set it & forget it

- Superior Sensor (Patent #5,473,245)

- Local indication with HMI display

- Dual compartment housing with separate field terminal compartment

- Loop powered to 22m (75ft) probe length

- Total and/or interface level measurement

- Pressure to 165.48 bar (2400 psig) Std. 124.1 bar (1800 psig)

- Temperature range: -195.5 to 426.6ºC (-320 to 800ºF) with options

- Field replaceable/upgradable electronics module

- Built-in RFI/EMI filter

- Digital communications

- Two level indications

- RTD for process temperature measurement

- Glass viewing window

- 316/L Stainless Steel enclosure

- 21-point linearization table

Data

Overview

ABB's K-TEK level products' patented sensor technology allows the LMT series transmitters to be used in the most challenging of industrial level applications such as interface measurement, compressor level and separator level applications. In addition, the LMT Series Level Transmitters are the only magnetostrictive level transmitters in the world to be certified for use in SIL2 and SIL3 systems per IEC61508. Every day, we solve high accuracy and challenging applications. We can help you with yours. ABB's K-TEK level products' magnetostrictive transmitters are used extensively around the world to provide continuous level indication and transmission of an analog and/or digital signal for monitoring or control. The unique design allows increased level sensing resolution which is more than 100 times greater than a conventional reed switch type device. The Magnetostrictive Level Transmitter versatility allows direct in-tank installation (LMT100) or external mounting (LMT200) to a magnetic level gauge. HART and FOUNDATION Fieldbus options make our magnetostrictive level transmitters easy to connect digitally to most control systems.Customer benefits:

- High Accuracy

- High Reliability

- No calibration required

- No Maintenance

- Oil and Gas

- Petrochemical

- Chemical

- Power Generation

- Water and wastewater treatment

- Pulp and Paper

- Biotech

- Marine

Overview

Data

FEATURES

- Range to 50 ft. / 15 m

- Isolated 4 - 20 mA Output with HART 7

- Graphic LCD Display

- Integrated Analytical Software

- 5 Configurable Relays / 8 Amp

- Configurable as Open Channel Flow Meter

- Pump Cycling and Pump Monitoring

- Remote Totalizer Count Outputs

- Automatic Variable Gain & Power for Difficult Applications

APPLICATIONS

- Various Liquids Including Water Storage Tanks

- Moderate Range Solids Such as Loading & Bagging Hoppers

- Mineral Oil

- Open Channel Flow Measurement in the following configurations

- V-Notch

- Flumes

- Weirs

OPTIONS

- Transducers for Liquids & Solids

- Cable length of 10m, 20m, 30m 40m or 50m

- Aiming Kit

Overview

Data

- 10 amps rated DPDT switch (NO or NC contacts)

- Unique concept of magnetic coupling, eliminating direct contact with process

- No process piping or valves required

- Easy mounting and adjustment; only small screwdriver required

- Trip point infinitely adjustable without changing process piping

- Vibration resistant

- Compact design

- Suitable for high temperature applications

- Industrial Explosion Proof IP66/67 and NEMA4X enclosure with ATEX/IECEx, FM US and Canadian approvals

Overview

Data

- 10 amps rated DPDT switch (NO or NC contacts)

- Unique concept of magnetic coupling, eliminating direct contact with process

- No process piping or valves required

- Easy mounting and adjustment; only small screwdriver required

- Trip point infinitely adjustable without changing process piping

- Vibration resistant

- Compact design

- Suitable for high temperature applications

- Industrial Explosion Proof IP66/67 and NEMA4X enclosure with ATEX/IECEx, FM US and Canadian approvals

How do I determine which instruments I need and their cost?

This depends on what you are needing to control or measure, your operating environment, your specific process flow, and many other factors. Durkin’s process specialists can help you determine the specific process instruments (down to the part number) that suit your application, budget, and expected life-span the best. Call (314) 432-2040 or contact us.

What is process instrumentation?

Process Instrumentation are sensors and instruments used to measure and control process variables including levels, flow, pressure, temperature, pH, and humidity.

In-field instruments, such as flowmeters or temperature sensors, are close to the process or measurement point, or may even have process liquids flowing through them. Panel instruments not usually where the process is happening, but are rather located ina controlled room or with the line controls.

Common types of process instrumentation include: flow meters, rotometers, level sensors, temperature sensors, recorders (to record process data), actuators, valves, gas analyzers, positioners, and actuators.

What symbols are used for process instruments?

Depending on the program, plant standards, and engineering firm that did the drawings, symbols for process instrumentation can vary. You should have been supplied with a lead or legend sheet that defines the symbols for the particular set of drawings you are looking at. However, there are a common set of generally agreed upon symbols, examples of which you can reference here.

Robert Cook at AiCHe has put out an excellent blog post on interpreting and using instrumentation symbols. If that doesn’t help, contact Durkin and one of our team members can help you solve the mystery: (314) 432-2040

Do you only supply the brands listed?

We carry a wide-range of process instrumentation and solutions. You can see our full supplier list here, but we may be able to source brands or point you the right distributor for other brands. More importantly, we can help you determine the appropriate instrumentation and controls solutions needed to solve your process issues. Talk to one of our experts today: (314) 432-2040 or fill out a contact form.